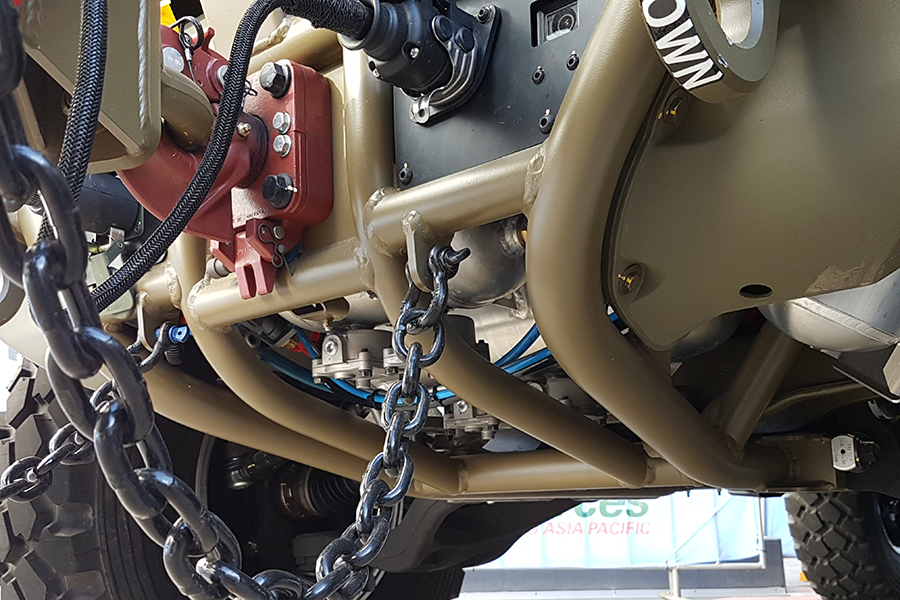

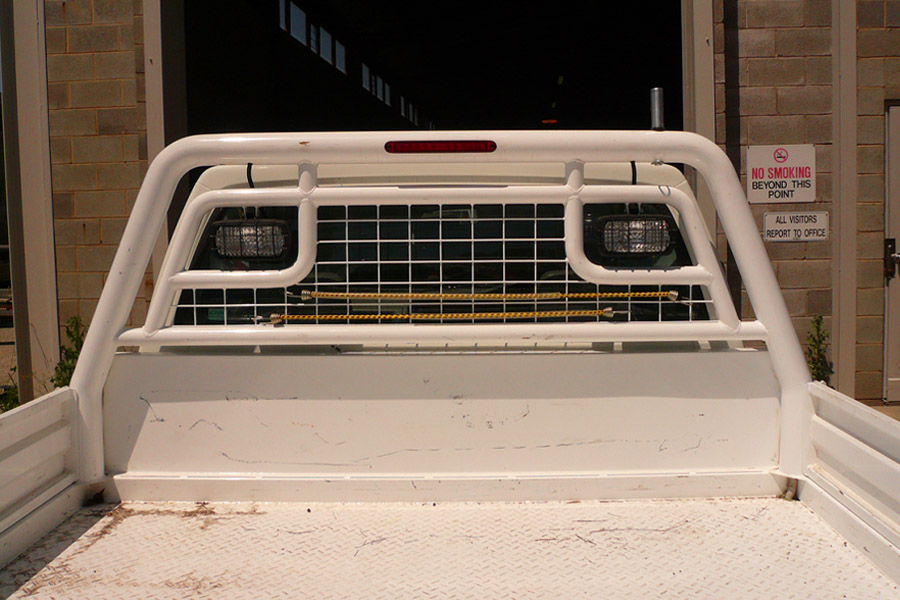

Bendcraft specialise in providing smooth distortion-free bends by using the latest technology in fully automatic three axis controlled mandrel bending machinery.

This ‘top-shelf’ equipment allows us to bend your componentry to the highest available levels of accuracy and repeatability whether it’s a single bend on one plane or several bends on multiple planes – Bendcraft has the answer.

A unique advantage of this technology is that bending of thin wall material, even with tight radii, is achieved without any flattening or collapse of the section. The result is quality full-profile bends time after time!

Specifying bend detail.

For accuracy when ordering Bendcraft mandrel bent sections and components, please provide the following information if possible:

- Material dimensions – outside diameter and wall thickness

- The centreline radius of bend

- The bend angles required

- The distance between the bends

- The type of material required for bending eg: mild steel, stainless steel, aluminium

- Dimensioned drawings or existing samples.

Tips when designing a component.

Try to allow a minimum straight section between bends of approximately 2.5 times the outside diameter of the pipe or tube.

Please enquire as to which types of stainless steel and aluminium are most suitable for bending. Also ask what centreline radius’ are available or possible for the tube or pipe size you would like to use.